Automotive Parts

6 Top Benefits of HME Machining CNC Machining in Automotive Industry

Our Most Commonly Provided Items

Surface Finishing We Use

◆ Sanding

◆ Sandblasting

◆ Painting

◆ Electrophoretic Coating

◆ Chrome Plating

◆ Galvanizing

◆ Nickel Plating

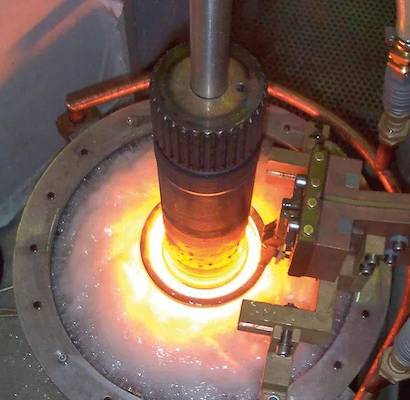

◆ Heat Treatment

◆ Spraying

◆ Polishing

Raw Material We Use

◆ Aluminum Alloy

◆ Stainless Steel

◆ Titanium Alloy

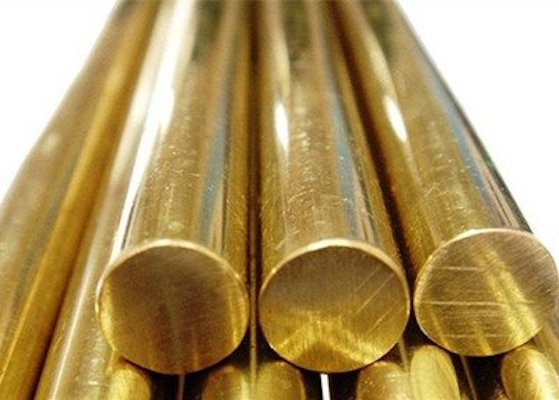

◆ Copper

◆ Plastic

◆ Nylon

Attention:

Different materials have different physical and chemical properties, so we will comprehensively consider factors such as performance, cost and processing difficulty when selecting materials. Of course, your wishes come first.

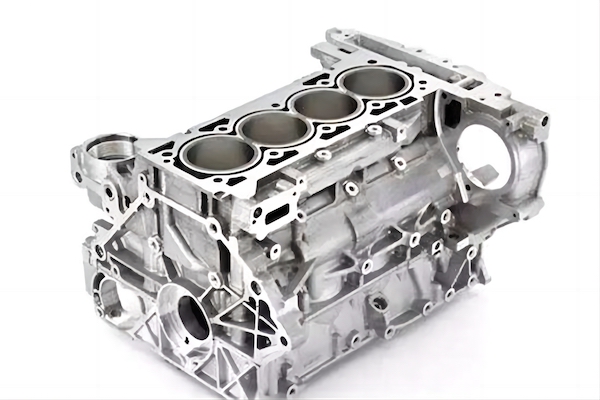

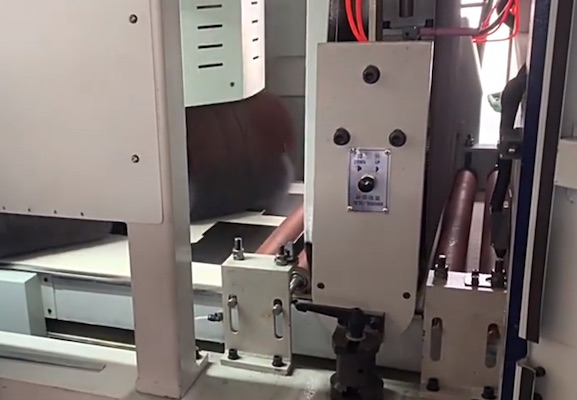

CNC Machining In Modern Automotive Parts Manufacturing

As a high-precision, high-efficiency digital control processing method, CNC machining has always been the preferred method for modern automotive parts manufacturing.

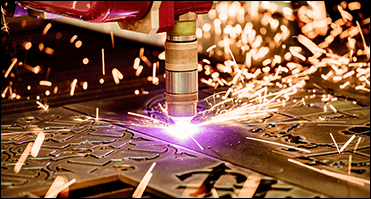

Compared with other digital control processing methods, such as 3D printing, laser cutting, etc., CNC machining has advantages of higher machining accuracy, better repeatability, wider range of machining, especially for the processing of metal parts.

Although its cost is relatively high, CNC machining is still an important part of the automotive manufacturing industry because it can ensure machining accuracy and quality, while having higher machining efficiency.