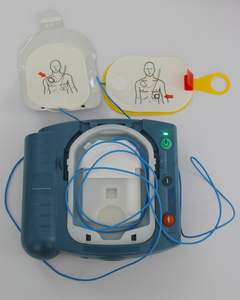

Medical Parts

6 Top Benefits of HME Machining CNC Machining in Medical Industry

Our Most Commonly Provided Items

Surface Finishing We Use

◆ Oxidation

◆ Sandblasting

◆ Polishing

◆ Plating

◆ Spraying

◆ Anodizing

Raw Material We Use

◆ Titanium Alloy

◆ Stainless Steel

◆ Nylon

◆ Plastic

◆ Silicone

◆ Carbon Fiber

Attention:

Different materials have different physical and chemical properties, so we will comprehensively consider factors such as performance, cost and processing difficulty when selecting materials. Of course, your wishes come first.

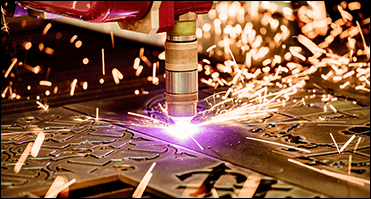

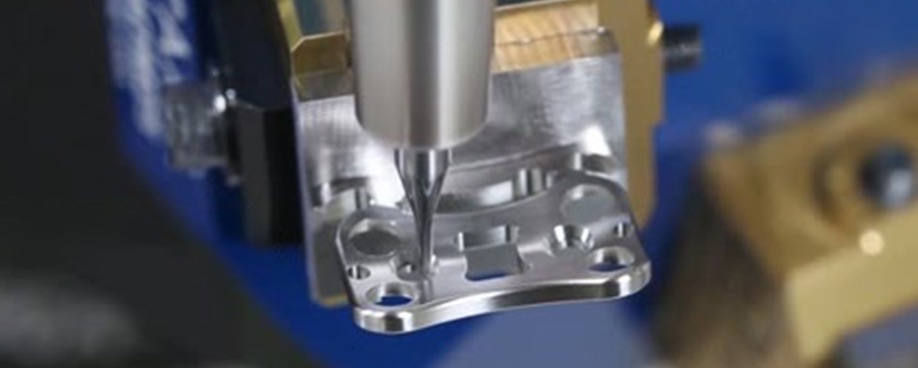

CNC Machining In Medical Manufacturing

The use of CNC machining In Medical Instrument Manufacturing has greatly improved the quality and reliability of Medical Instruments, making them more effective in diagnosing and treating patients.

CNC machining can precisely control the movement & cutting speed of processing tools and efficiently manufacture complex medical device components, such as joint implants and dental implants.

CNC machining can also produce small batches and customized parts of medical devices, which is unmatched by traditional production methods.