Industrial Machinery Parts

6 Top Benefits of HME Machining CNC Machining in Industrial Machinery Industry

Surface Finishing We Use

◆ Sanding

◆ Sandblasting

◆ Painting

◆ Electrophoretic Coating

◆ Chrome Plating

◆ Galvanizing

◆ Nickel Plating

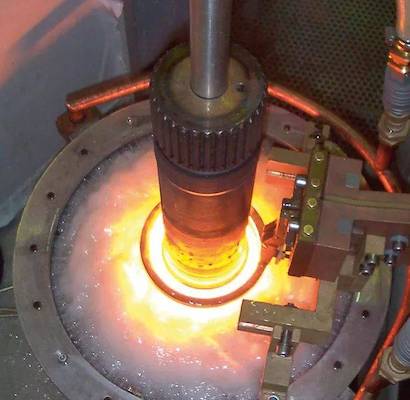

◆ Heat Treatment

◆ Spraying

◆ Polishing

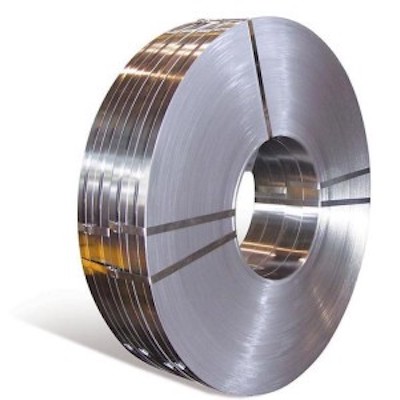

Raw Material We Use

◆ Aluminum Alloy

◆ Stainless Steel

◆ Titanium Alloy

◆ Plastic

◆ Carbon Steel

◆ Cast Iron

Attention:

Different materials have different physical and chemical properties, so we will comprehensively consider factors such as performance, cost and processing difficulty when selecting materials. Of course, your wishes come first.

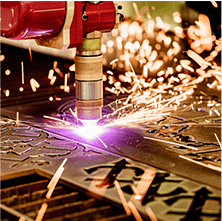

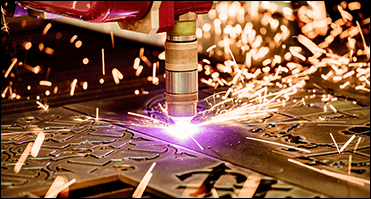

CNC Machining In Industrial Machinery Manufacturing

CNC machining has revolutionized the manufacturing industry, providing high precision and efficiency in the production of industrial machinery parts and components.

Production rate, safety and stability are the main advantages of CNC machining over traditional machining. It allows manufacturers to produce complex shapes that are nearly impossible to create manually, avoiding material waste and reducing costs.

In the field of industrial machinery manufacturing, CNC machining has become a critical tool for producing high-quality, complex parts with tight tolerances.