◆ Processing with 4-axis CNC machine

◆ Made of aluminum alloy

◆ Sandblasting, electrophoretic coating & anodizing surface treatment process

◆ Finished surface roughness Ra (μm) 1.2

◆ Diameter tolerance (μm)±50

◆ Circular runout tolerance (μm)±20

◆ Roundness tolerance (μm)±20

◆ Parallelism tolerance (μm)±20

◆ Thread hole tolerance (mm)±0.1

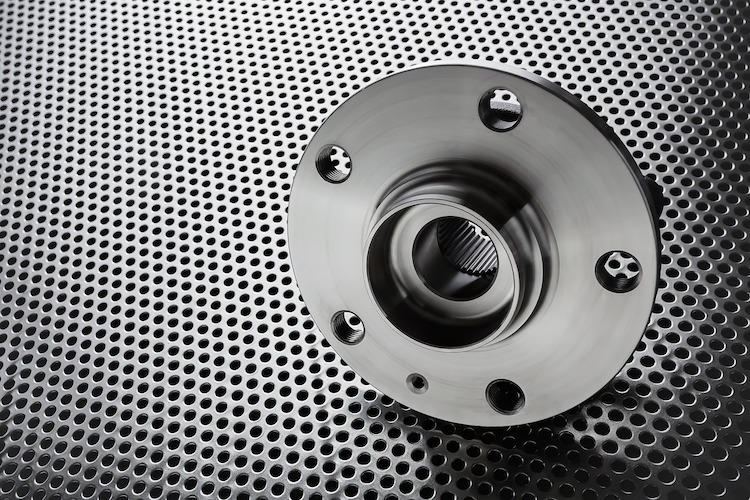

Wheel hub is used to support the weight and rotational force of vehicle and convert the rotational force of the vehicle to enable it to move. Wheel hub needs to have sufficient strength and stiffness to withstand the dynamic loads and impact forces generated during vehicle is running.

HME Machining utilizes 4-axis CNC machining to complete the complex axial hole processing of the hub, and uses lighter aluminum alloy to reduce the overall weight of the vehicle and improve fuel efficiency. Sandblasting enhances the product's abrasion and corrosion resistance, while the combination of electrophoretic coating and anodizing further improves surface hardness and glossiness. The final product boasts a surface finish of 1.2 microns, the diameter tolerance of ±50 microns, the circular runout tolerance of ±20 microns, the roundness tolerance of ±20 microns, the parallelism tolerance of ±20 microns and the thread hole tolerance of ± 0.1 millimeter.