CNC Turning is a common machining process used to produce cylindrical and conical parts. Similar to CNC Milling, CNC Turning involves using computer numerical control (CNC) technology to control the cutting tool's movements on the surface of the workpiece.

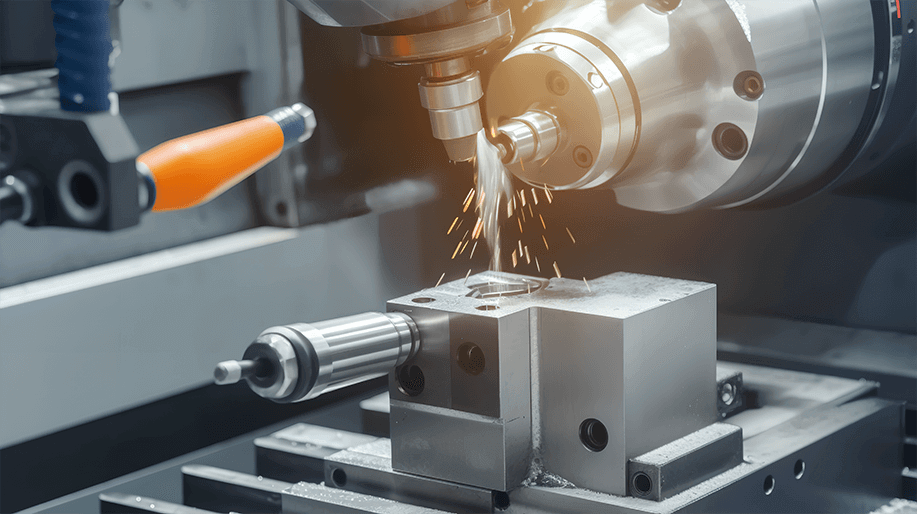

The basic principle of CNC Turning is to mount a cutting tool on a rotating workpiece and control the tool's movements on the workpiece surface through a CNC system to achieve the desired geometric shape. CNC Turning offers several advantages, including efficient machining of round parts and high precision and surface quality.

In CNC Turning, the workpiece is typically clamped on a rotating spindle, and the CNC system controls the spindle's rotation speed and direction. At the same time, the cutting tool is fixed on a CNC-controlled slide, and the slide's movement is controlled to determine the cutting position and depth. CNC Turning encompasses various cutting and shaping operations, such as outer and inner diameter cutting, thread cutting, grooving, drilling, and more.

CNC Turning finds wide applications in the manufacturing industry, particularly in automotive, aerospace, and medical equipment sectors. Compared to traditional machining methods, CNC Turning offers higher production efficiency, greater precision, and better consistency.