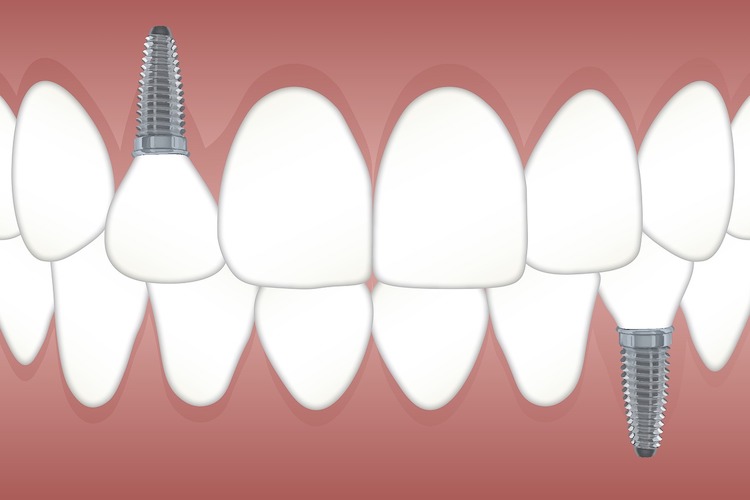

Dental Implant plays an important role in the treatment of tooth loss. It can replace missing natural teeth, help patients restore oral health and normal chewing function. International standards (such as ISO 14801) and national regulations have specific manufacturing and inspection standards for it.

HME Machining utilizes 4-axis CNC machining to ensure the accuracy and standardization of the finished product. In terms of material selection, we utilizes zirconia, which has been widely praised in recent years. It is closer to the color of natural teeth than titanium alloy and has good biocompatibility & mechanical properties too. Considering the product will be combined with the bone, we utilizes acid etching to increase its surface roughness, thereby increasing the bonding force with the bone after implantation. The final product boasts a surface finish of 0.2 microns, the diameter tolerance of ±0.1 millimeter and the length tolerance of ±1 millimeter.